Solar plants are changing. From one-size-fits-all towards well-adapted systems that give better technical answers to the most common cost problems. With these posts I’d like to contribute with new technologies that I’ve developed over the last couple of years.

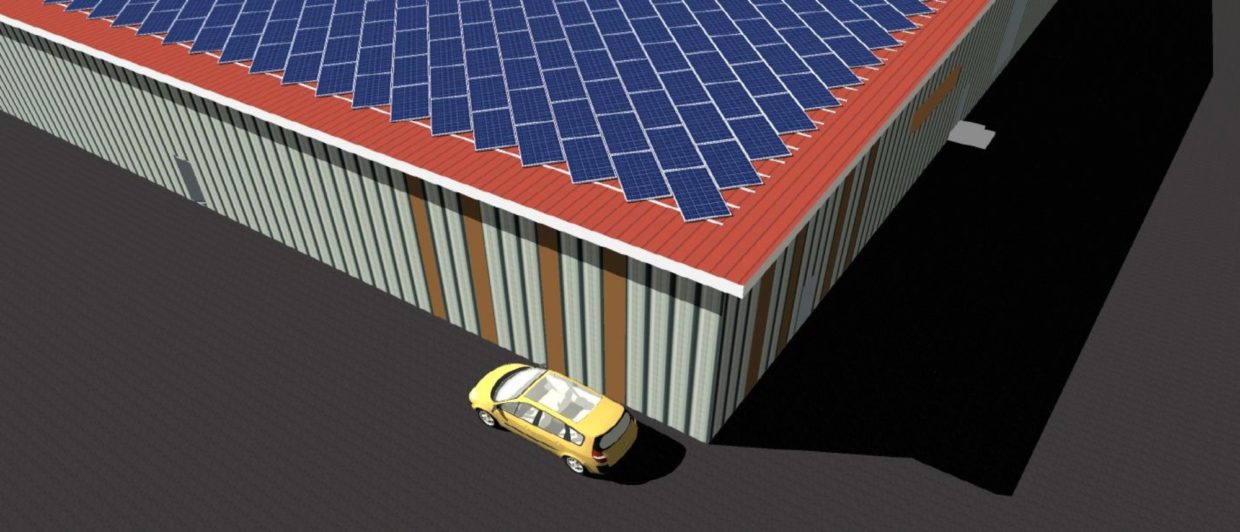

In my previous articles I’ve showed several variations of the X-panel solar technology for utility-scale solar parks. These arrangements all help the solar panels to stay clean due to better evacuation of (dirty) water. However, the X principle can be very beneficial for pitched roofs, too – especially for all those industrial buildings with typical slopes between 5 and 15 degrees that are common in Europe and in other parts of the world. In this article I’ll discuss how to apply X-panel on these roofs.

Like before you’re always very welcome to discuss the systems. Please feel free to like or share this posting. You can also invite me to your personal LinkedIn network if you would like to discuss these technologies personally. Please note: We do not manufacture solar products, e.g. solar racking systems. We are offering direct licenses to solar project developers on a pay-per-site basis.

solar plant design (5): X-panel for pitched roofs

Addressed solar problem:

- yield losses due to soiling

- higher maintenance cost due to faster cleaning cycles

- or: higher system cost for frameless panels and/or special racking

Most of today’s solar panels are embedded in aluminum frames. At low slope angles the lower frame rail of the panel builds a horizontal raised rib at the lower edge of the module. This rib causes a back-water effect. The filthy water is not correctly run off resulting in the accumulation of dirt on the glass alongside the lower frame rail. This often results in significant loss in yield.

Modules can be elevated if the roof pitch doesn’t allow for flat installation. However, space utilization is reduced.

Today there are two main methods to overcome this problem on pitched roofs: You can use frameless solar panels. The systems cost for these panels are usually higher than for standard framed modules, and they’re very sensitive, so the loss ration is much higher. Another option is to use special racking systems that elevate the panels at their “high side” in order to raise the slope angle (see picture). Again, system cost are higher here, and you loose power per sq.ft. since you have to keep a distance between the lines (to avoid shading), while at the same time the wind loads go up.

X-panel solution: rotate the panel. Job done.

If the panel is rotated in its own plane, the horizontal corrugation disappears, and soiling effects are eliminated.

Like for the ground-mounted X-panel systems, the X-panel overcomes this problem on pitched roofs in a simple, yet extremely effective way: By rotating the panel on its own plane, the horizontal corrugation disappears. The lower frame rails now both show slopes ensuring proper runoff of rainwater. Thus the panel will remain clean, even at slope angles of only a couple of degrees (see pictures on the right).

X-panel variations for pitched roofs

There are at least three workable ways to install solar panels after a rotation. All of them make sure that the solar panels are clamped within the “high load” clamping areas specified by the panel manufacturer, thus ensuring maximum load capacity. And all these variations can be mounted with most of today’s standard racking systems. It’s the same rails, same clamps, same bolts.

The first two variation use horizontal rails. In the first variation the panel is rotated (e.g. 10 degrees) just enough to assure that the clamps still stay within the specified clamping areas. In the second variation the rotation angle is something like 40 to 45 degrees (depending on the solar module size). Again, the rails cross the clamping zones. In the third variation the racking system is rotated together with the modules into the desired position. That’s all.

To sum up, the main benefits of “X-panel for pitched roofs” are:

- perfect self-cleaning capabilities for reliable energy yields

- solid structure for secure attachment of the modules

- no additional wind loads, the modules stay close and parallel to the roofing

- high energy yield per sq.ft., same narrow gaps between the modules like before

- fast and easy installation

- and of course: standard low-cost racking