the flatter, the better?

Large ground-mounted solar plants have changed a lot over the last decade. Especially in areas with high land and labor costs, panel slopes have become increasingly flatter and the panel rows now show tighter alignment. Ten years ago, the typical slope for ground-mounted systems in Germany was around 32+ degrees. In 2016, most of the new installations showed slopes below 20 degrees, with some systems coming down to 12 or even 10 degrees. Nowadays, the typical ground coverage ratios have come up from around 0.3 in the past to 0.75 or more. The same development can be observed in other countries like Italy, England or Japan.

it’s all about lcoe

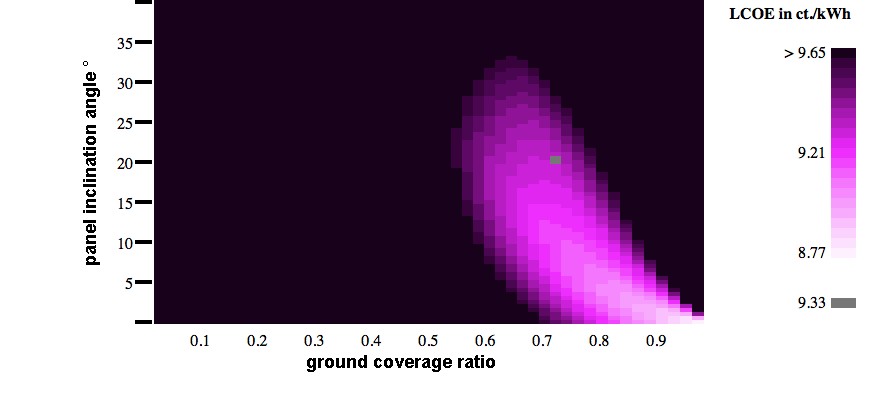

LCOE-Optimizer 0.9, our own software tool to determine the best arrangements for a given local cost structure.

The reason is: Declining prices for solar panels, inverters and racking have caused a shift in the cost structure of large PV systems. Unlike in the past, increasing the amount of panels on the ground now reduces the levelized cost of electricity generation (LCOE). Ground coverage ratio is key. In order to get a better ground coverage, you have to lower the slope angles. Otherwise, the shading effects between the panels rows would reduce energy yield signifcantly. In fact, by reducing the slope angles, every single solar panel looses some energy yield because of the fact that it is repositioned a little bit “out of the sun”, but at the same time you overcompensate that effect by effective cost savings due to increased ground coverage. It sounds illogical at first, but it pays off. If you loose, for example, 10 percent of the production per kWp, while cutting the cost per kWp by 12 or 14 percent , you will get better electricity generation cost.

current limits

Prices for solar panels as well as BOS costs will very likely continue to fall. In contrast, cost for land and labor, as well as “soft costs” will not. The shift from “variable costs” towards “fix costs” will continue for both the initial and the operational costs for solar plants. Therefore, every price drop in solar hardware will raise the pressure to make better use of existing lots. However, today’s south-facing systems are reaching a limit: If you install your panels too flat, you will have significant yield losses due to soiling effects.

We heard about numerous installations where framed standard solar panels had been installed almost flat on the ground (ground-mounted as well as flat roof), and the results were disappointing: backwater-effect, dirt-accumulation on the panels, insufficient self-cleaning, frustrating energy production losses. Although you have to go as low as possible, a slope that is too low (e.g. 12 degrees of slope or less) will not work.

future systems

solar systems will fully cover the allocated surfaces. it’s simply cost effective.

There is a growing need for new, reasonable solar panel arrangements that can exceed self-cleaning limits, and, are therefore, able to cover 80, 90 or even 100 percent of the given surface. That’s especially true for the most commonly used solar panels, aluminum-framed crystallin modules. With the diamond roof technology and the X-panel technology, solidenergie shows two more effective solutions in arranging panels with respect to the actual cost situation in high price countries. And there are more to come.