contents:

(1) – basic principles

(2) – ground mount applications

(3) – flat roof applications

(4) – prototypes

(5) – wind tunnel testing

(6) – state of play

(1) basic principles

diamond roof: What it is

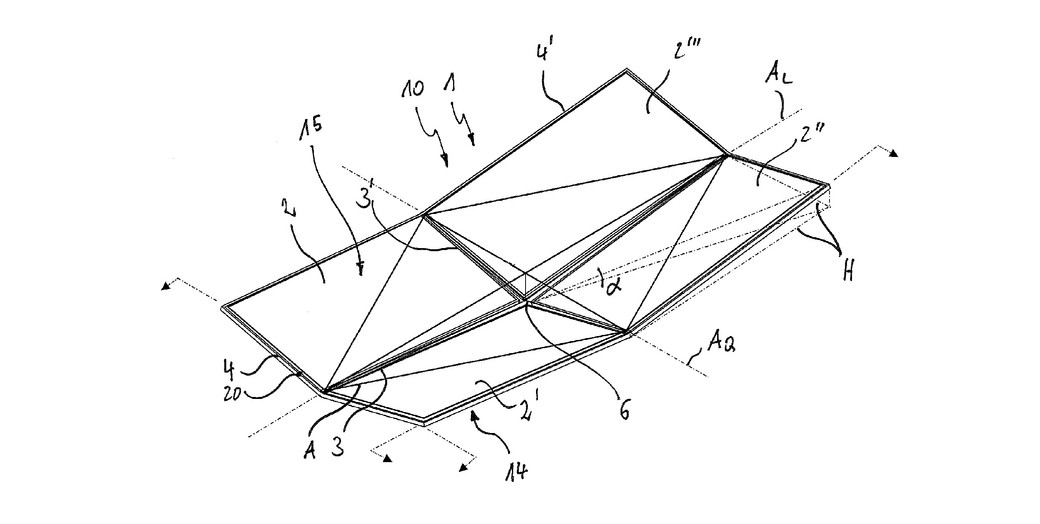

The diamond roof is a patented way to arrange standard solar panels on plane surfaces like open fields or flat roofs. The basic geometry is built by units of four solar panels that form together a shallow pyramid. These pyramids are then installed against one another to form a continuous solar panel structure that covers the entire surface. We called it diamond roof because the structure resemble cut gemstones.

main characteristics

more annual energy yield on any given surface

Unlike south-facing solar systems a diamond roof does not need to keep distances between the panels lines. The ground coverage ratio is close to 1. For this reason, a diamond roof installation will produce more energy on a given surface than any other solar panel arrangement available today. It will thereby show a less pointed daily production curve, allowing for easier energy management and downsized inverters. At the same time, the diamond roof ® showed excellent aerodynamic qualities in wind tunnel testing. This allows for reduced material usage, further lowering SBOS cost.

main applications

The diamond roof shows its advantages when the goal is to maximize the annual energy yield on plane surfaces. The main applications are ground mounted systems and systems for flat industrial roofs. However, the beauty of this particular panel arrangement has opened new doors in the area of architectural integration.

(2) – ground mount applications

more energy yield per acre

more than 600 kWp/acre – with common 260 Wp-panels.

Current cost structures for ground mounted solar systems demand for maximum ground coverage in order to reduce the electricity generation cost (see also “Thoughts on future solar plants”). Diamond roof ground mounted systems fulfill this requirement better than any of today’s south-facing or east-west-facing solar installations. The diamond roof designs show ground coverage ratios between 0.90 and 0.98. With the use of standard 260 Wp solar panels this adds up to around 630 kWp per acre (more than 1.5 MWp per Hektar). Because of the flat structure, the self-shading effect is marginal. The unique method of inclining the panels assures that the self-cleaning effect stays intact, despite the low slope angle. The yearly energy yield per kWp is very good, the yearly energy yield per acre is second to none.

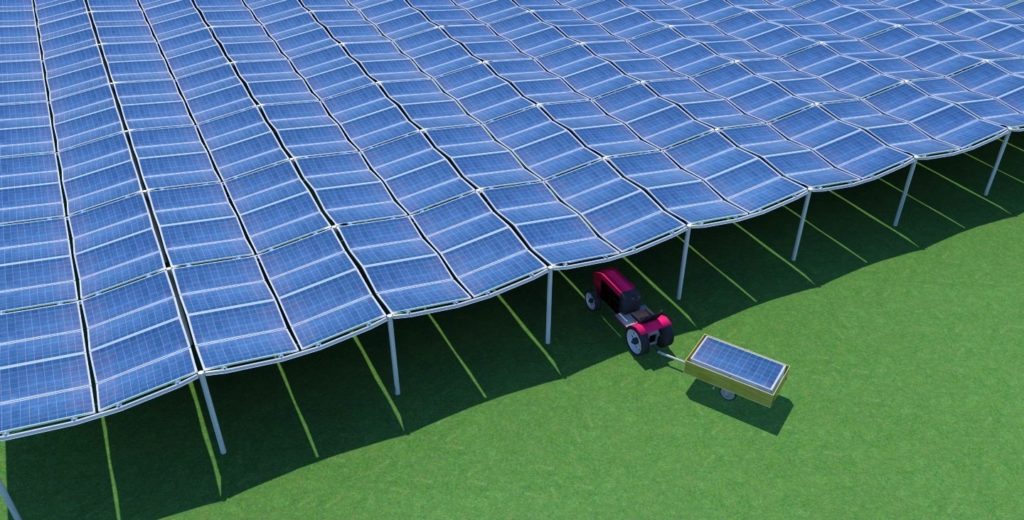

Large distances between the poles and up to 4 meters of clear headroom: diamond roof systems offer a lot of additional space which can be used for animals, plants, storage or whatever is needed.

less steel per kWp

The decline of solar module prices has raised the price pressure on BOS components, including racking systems. The main driver for rack manufacturing cost is the amount of steel that is used. The profiles of the racking systems have been optimized aver the years, and many experts agree that the possibilities to further reduce the steel usage for current racking solutions are largely exhausted.

stability with a lot less steel

The diamond roof now breaks this deadlock. Its unique geometrical design allows for a new kind of racking, in which the substructure is executed more like a “steel hammock”, comprising rods that have bends or kinks at defined positions (see also “S-panel”). Forces are now directed in a new way, and while bending forces are largely eliminated, the weight of the system is significantly reduced. solidenergie is preparing to display the production prototype for a diamond roof ground mount racking at INTERSOLAR 2017.

(3) – flat roof applications

more panels, less ballast

Better ground coverage and reduced ballast on industrial roofs. And maybe an additional pitch of beauty.

When it comes to choosing a pv system for a large industrial roof, there are usually two key requirements: The system should produce as much energy as possible in order to make the installation more profitable. Furthermore, it should be as light as possible in order to correspond with the restricted load limits of today’s industrial buildings. That is why in Germany nowadays eight out of ten solar installations on flat roofs are east-west oriented systems, with other countries showing the same development. East-west systems allow for more panels on the same roof than south-oriented systems. Also, the better aerodynamical properties make it possible to significantly reduce the ballast that is needed to secure the modules on the roof. However, a diamond roof flat roof system outperforms today’s flat roof systems in both ground coverage ratio and ballast requirements.

more of the same panels on the same roof

The diamond roof needs 40 percent less space for access paths without any reduction in accessibility.

When we present the diamond roof system for flat roofs, people quite often think that in terms of ground coverage ratio an east-west system and the diamond roof are equal. They are not. In fact, using standard 60-cell-modules, the unique diamond roof geometry allows you to install about six percent more of the same panels on the same roof. Through switching from 60-cell-modules to the newer 72-cell-modules, the advantage will increase to eight percent.

The reason lies in the structure of the access paths between the panels. For east-west systems, these paths typically run along the long side of the solar modules. In the case of diamond roof flat roof systems, it is the short side. Given a walkway width of 1.3 feet, for example, an east-west system needs some 3.6 sq ft of acces path per solar panel to assure access, while this space is reduced to 2.2 sq ft per panel if you install them as a diamond roof. This saved space is used to install the additional panels.

Less ballast per panel

It’s not the weight of the solar panels nor the weight of the racking that limits the possible uses of a given flat roof pv system. Its the ballast that is required to secure the position of the panels. This ballast is determined by the aerodynamic qualities of the panel arrangement.

Extensive boundary layer wind tunnel testing has shown that the “bumpy” structure of the diamond roof together with its flatness has significant advantages over most of today’s flat roof systems when it comes to ballasting needs. If a given flat roof won’t carry the diamond roof, it probably won’t carry anything else on the market.

(4) – prototypes

about prototypes

“If I had asked people what they wanted, they would have said faster Horses

-Henry ford-

It took us some time to figure out the value of prototypes and the “proof of concept”. Even today some solar decision-makers understand “proof of concept” as the proof that the new product is actually both better and cheaper. Otherwise, they say, it doesn’t make any sense to bring it to market. This approach is correct if the goal is to improve existing products, e.g. mounting clamps that show the same strength like the old ones but reduce the material usage by two percent.

For truly new products a different approach might be more useful. Truly new products are products that offer additional benefits that go beyond existing solutions. These have much more potential to win new customers than improved versions of existing solutions.

“Make sure you are building the right it, before you build it right!

-A. Savoia-

Therefore, the focus for the “proof of concept” should be much more on market appeal than on technical feasibility. In an age where we have the technology to send people to Mars, it is equally possible to mount solar panels in any way. The more important question to be answered is: Will the customers accept the new product? So the real purpose of building prototypes is to validate, objectively and with the smallest possible investment of time and money, the market appeal of a potential product. For this reason, we build simplified versions and discuss them with customers. The feedback gathered from those discussions are then taken back to the drawing board resulting in a newly adjusted and improved prototype. This efficient, developmental approach leads to high quality products that are in line with market expectations and, of course, to a couple of test customers that are waiting for the new product to be ready to ship; a proven concept.

ground mounted System

Immediate verification of the strength calculations: A prototype, four water containers and some 85 gallons of water.

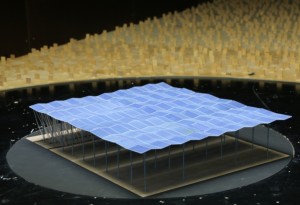

We have built and tested several very different prototypes for a diamond roof ground mounted system. After filing for additional patents for the substructure, and completing the necessary physical stress tests, one of the first prototypes was presented at the INTERSOLAR Fair in Munich in 2014 in order to test international reactions. We were pleased to have received positive responses. Even more important was the fact that we learned a lot about possible applications of the technology that we hadn’t considered before. This helped us in determing the primary focal points of the system. It was this knowledge, derived from first-hand customer experience, that provided the framework for our latest prototypes.

During the summer of 2016, we built new prototypes for the diamond roof ground mounted system in cooperation with MKG Göbel, a leading German EPC company. The substructure had changed, and the components were now closer to standard solar racking parts. Moreover, it seemed that the new mounting procedure will not hurt installation time compared to standard south-facing racks. But we still faced some problems due to the 3D-structure of the solar panels. That forced us to rethink the system again and to finally invent those “steel hammocks” to solve the geometrical challenge. As of May 2017, the patent for this technology is pending, and the production prototype is ready for being show at Munichs INTERSOLAR

Flat Roof System

We have worked on a diamond roof flat roof racking system based on cones made of EPP. This mounting system arose from a collaboration with a German automotive engineering company, and it reached a maturity level of 90 percent as well as excellent audience reactions. However, for a variety of non-technical reasons we postponed this project and gave priority to ground mounted diamond roof systems and to various applications of the ground mounted X-panel technology. After having licenced out the diamond roof ground mount system, we have restarted the work on a highly efficient racking system for diamond roof flat roofs in autumn 2016. The basic design for the system is ready, the next prototype is on its way.

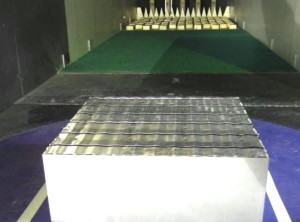

(5) – wind tunnel testing

aerodynamic properties of the diamond roof

Certificates according to “Eurocode 1 – Actions on Structures” have been issued for both roof mounted and ground mounted diamond roof structures.

The mechanical loads on pv systems that occur during strong gusts of wind are determined by the ability level of the system to equalize pressure difference. This ability is influenced by several design factors including front face, “roughness” of the module surface, and the degree of fragmentation of the enclosed volumes of air. In preliminary talks, experts agreed that the unique structure of the diamond roof will act very beneficial in terms of load (and thus in terms of material usage). However, since the diamond roof structure differs from standard south-facing panel arrangements in almost all of these factors, a lot of time had to be spent with wind tunnel testing. As expected, the estimations proved to be true for the flat roof system, as well as, the ground mounted versions. The diamond roof has, without a doubt, exceptional aerodynamic qualities.

Ground mounted

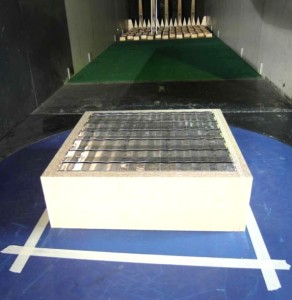

Prof. Wacker ran six different tests, including a closed diamond roof structure for heights up to 13 ft. (4.0 meters).

The wind tunnel testing for ground mounted diamond roof systems was performed by Prof. Jürgen Wacker from Wacker Ingenieure. He and his team tested several variations including pyramid-like, shell-like and saddle-like designs at different heights in their own boundary-layer wind tunnels. The results were very pleasing: Each single variation showed significant wind load reduction compared to south-facing pv installations. In contrast to standard 25 degree substructures, the decrease in mechanical loads was between an astounding 50 to 70 percent. This means that – especially in regions where snow loads have little influence – cross sections of the substructure can be minimized substantially. Moreover, structurally weaker and, therefore, more inexpensive solar panels can be implemented even in the windiest regions. Both factors help to considerably reduce BOS cost.

flat roof

This model was used to test the wind loads when there is no distance between the solar panels and the roof edge.

The wind tunnel testing for diamond roof systems on flat roofs was performed by Dr. Thorsten Kray from the institute for industrial aerodynamics. Dr. Kray and his team examined the performance of the system in relation to the distance to the roof edge. They also examined the resulting loads for the substructure under specific loading conditions. Again, we were very happy with the results. In terms of uplift forces, the diamond roof is on a par with today’s most advanced, aerodynamically optimized east-west systems, while lateral forces are even a bit better. That simply means less ballast per panel on any given roof. Should a given flat roof be too weak to carry the diamond roof, it will probably not be able to hold any other racking solution available on the market.

(6) – production systems

Fach charging stations

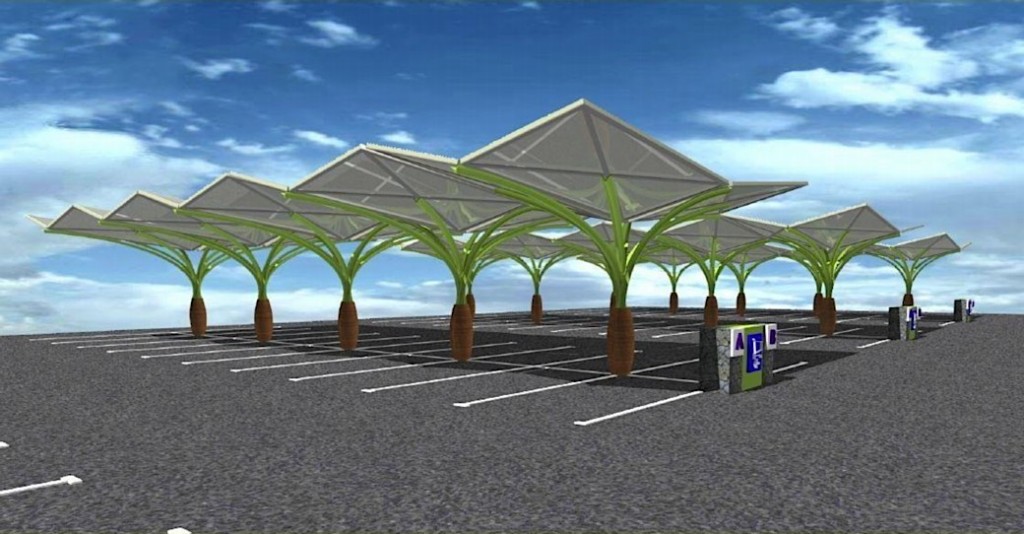

Fastned BV has built hundreds of “diamond roof” fast charging stations for electrical vehicles all over Europe.

Justus Well 2017-03-07

Could you show diagramms of daily energie production in dependence of the geographical latitude where is seen the contrast to east-west or south orientation?

For which latitude ist diamond roof best?

mirko_dudas 2017-03-07 — Post Author

As there are currently no production diamond roof systems installed, we have to rely on simulation data. Simulations for diamond roof installations are showing a behaviour that is almost identical to an east-west-system (with the same tilt angle of e.g. 10°). This refers to the total energy yield as well as to the daily production curve.

There is a small theoretical advantage towards diamond roof given by a slightly better diffuse light conversion rate. In pratice we expect the difference to be more significant due to the better self cleaning capacity of the diamond roof (10° east-west-systems tend to have serious energy losses due to soiling effects).

There is no specific latitude (range) that is best for diamond roof. It’s much like with east-west-systems: If ground is limited (and therefore expensive) and labour cost are high, east-west might be the better (= more economic) choice compared to south-facing (or in the southern hemisphere north-facing) solar installations. This might be true for the Ivory Coast as well as for Norway.

Rule of thumb: If for a given location an east-west system is more economic that a south-facing one, then diamond roof is more economic than east-west.